© Engl GmbH

Dynafit Headquarters: Demanding special civil engineering

Are you familiar with geotechnical planning and excavation safety? These are critical elements in the construction industry, especially when it comes to special foundation engineering. It’s essential to ensure that the ground is stable and safe before any construction work can begin.

That’s where companies like Grund & Boden Geotechnik GmbH come in. They specialize in providing geotechnical planning services, as well as designing and calculating excavation safety and dewatering systems for special foundation engineering. Recently, they were commissioned by the executing special foundation engineering company Engl GmbH for their expertise.

In this blog article, we will delve into the importance of geotechnical planning and excavation safety in construction, and take a closer look at how companies like Grund & Boden Geotechnik GmbH use their expertise to ensure safe and efficient construction projects. We will also explore the challenges that they face and the solutions they use to overcome them. So, whether you’re a construction professional or simply interested in the industry, keep reading to learn more!

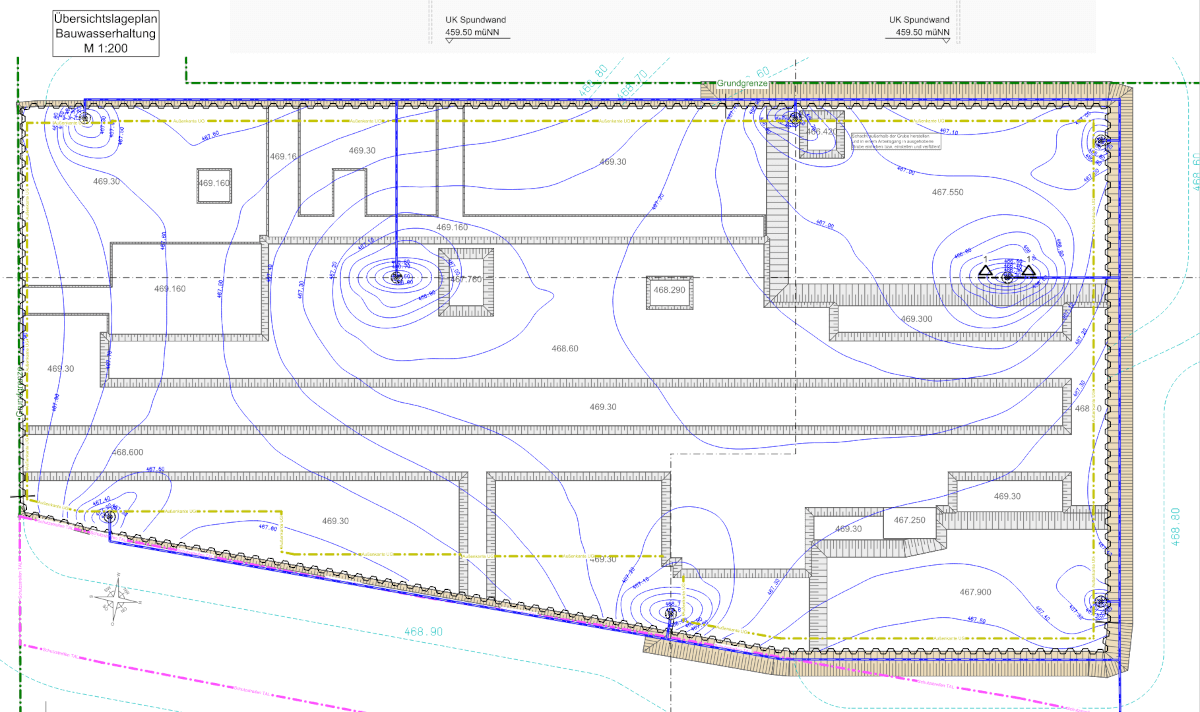

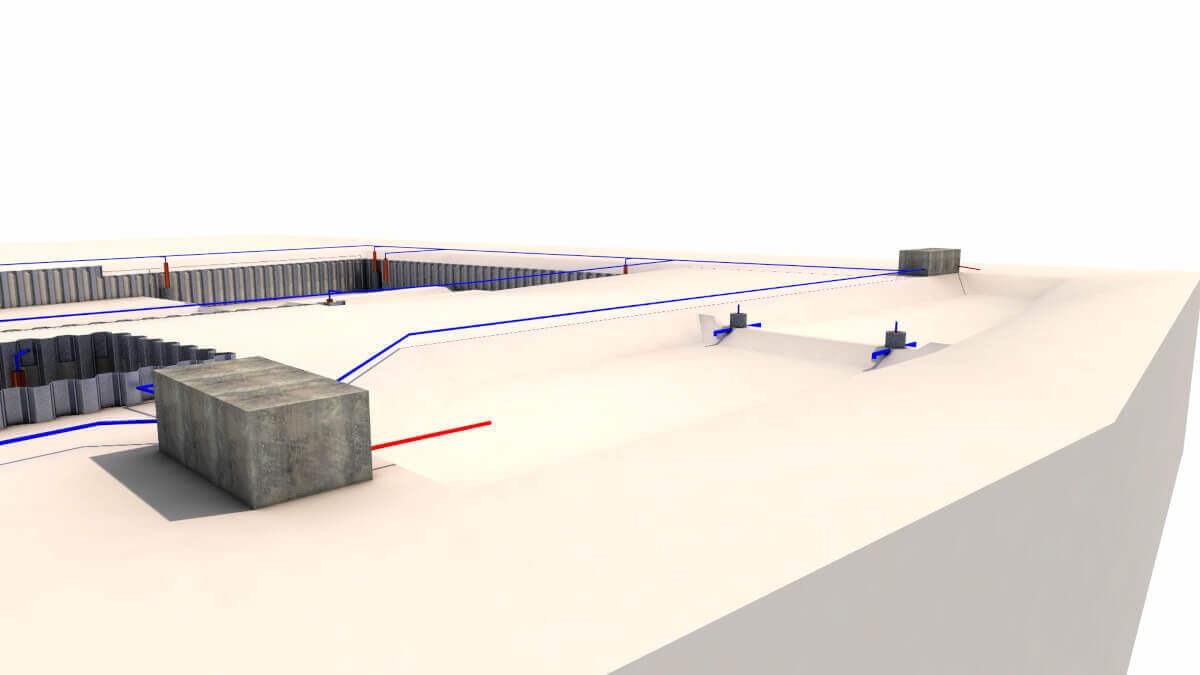

Lowering the groundwater level on 3,700 square meters

The extreme groundwater levels posed the biggest challenge for the construction project in Tyrol. In order to allow for the construction of the planned basement, the groundwater level had to be lowered by up to 2.7 meters on an area of approximately 3,700 square meters. At the same time, it was necessary to completely enclose the construction pit with sheet piles, which serve to support the up to four-meter-high excavations and partially seal the pit laterally. This posed a significant challenge for the geotechnical engineers involved in the project.

Diverting 100 liters per second

Another challenge was the lack of an available drainage system to divert the approximately 100 liters per second of water generated by the construction work. Neither a sewer nor a watercourse were within reach. As a solution, a drainage basin of around 500 square meters was built, equipped with two absorption wells, allowing the water to percolate back into the ground. This ensured that the construction site remained dry and free from any potential flooding issues.

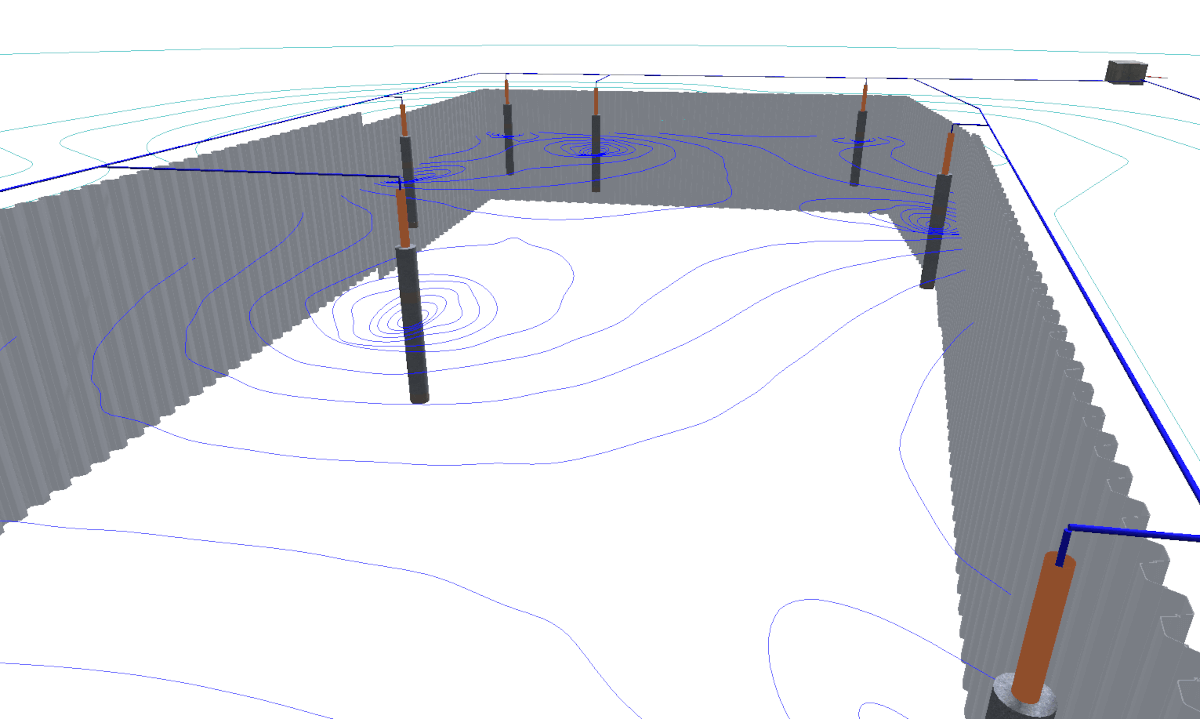

Complete 3D Planning with Allplan

All of these challenges were met by the engineers through a completely model-based planning process using Allplan software. The “Baugrube” add-on was used for the intersection of the excavation slopes and the calculation of excavation quantities. For excavation support structures, wells, and other special foundation engineering components, specially programmed SmartParts and PythonParts, which Grund & Boden Geotechnik has developed over the years, were modeled. In some cases, calculation results (such as 3D groundwater lowering lines) were transferred from other calculation programs into the model. For example, the SmartPart sheet pile provides a parametric BIM component that allows excavation support structures to be easily modeled and evaluated in 3D. Thanks to these intelligent components, the mass was accurately derived from the model, and the construction costs were precisely determined.

To experience Allplan Engineering’s innovative features, download the 14-day free trial now and bring your bridge projects closer to success.

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com