© iStockphoto LP / metamorworks

5 Key Trends for the AEC Industry in 2023

The architecture, engineering, and construction (AEC) industry has changed significantly in the past few years. The digital transformation is well advanced. Most stakeholders today are supported by digital solutions along the entire construction value chain. What sounds like the end of a journey is the beginning of a profound change in the construction and real estate industry based on using data in novel ways. 2023 will see technology become an even greater part of the design and construction process, with several key developments dominating the industry landscape. Here’s our predictions for the top 5 AEC digital trends of 2023.

AI-based Knowledge Management

One of the most useful developments that will unfold over 2023 is the change from solution-centric to data-centric project management. At the moment, BIM models, 2D drawings, and even non-graphical documentation can be managed using tools like the Bimplus cloud-based platform. This enables users to share 2D drawings and 3D models and link all available documents to the right objects in the BIM model.

This will become even more seamless and automatic by bringing artificial intelligence and machine learning into the process. For example, in the future, a set of drawings could be loaded into the cloud where an algorithm will determine which drawing belongs to which project and analyze if it matches to the existing 3D models — all with minimal human interaction. While planners might still deliver projects in 2D, this has advantages for many parties — saving time and increasing the quality of the design.

Automation in Design

Expect to see more data-driven design automation and parametric modeling. The rise of visual programming is facilitating customized automation for architects and engineers that have no scripting skills in the team. Tailoring CAD and BIM tools to be more aligned with the designer’s process will enable greater efficiency during the design process, at a time when consultancies are increasingly looking to improve productivity. Besides automating repetitive tasks in the design process, tools can also be developed to fulfil broader workflow needs, such as quality checks. Rule-based design analyses – such as those required to fulfil standards – are an area where automation will play a key role.

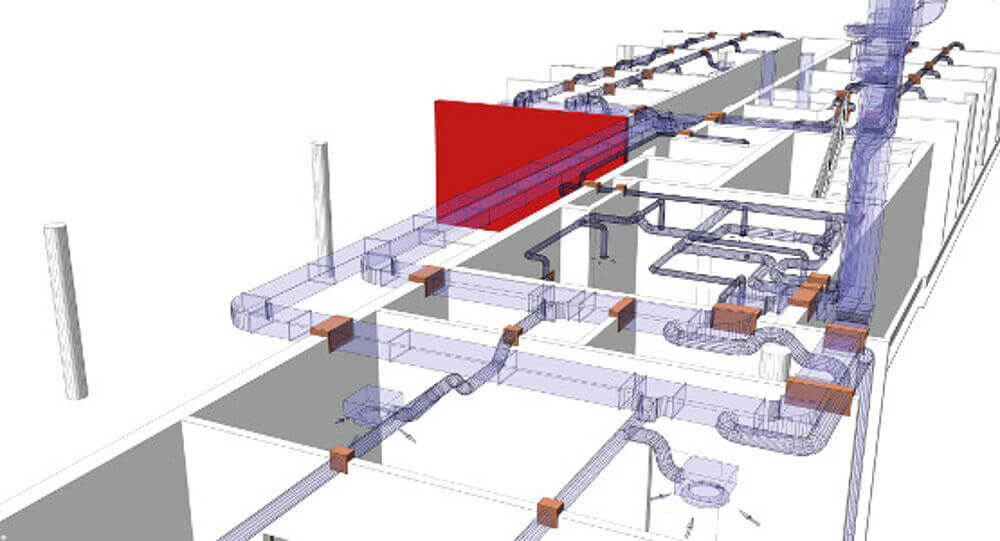

Automation in Execution

Automation will not just transform design, but also the manufacturing and construction processes. Prefabrication in particular – which is rapidly growing in adoption and use – accelerates the use of digital machines in construction. For example, precast concrete elements of any complexity can now be designed directly in Allplan, thanks to the merging of Allplan and Planbar. PythonParts can also be used to design precast objects rapidly while enabling changes to be made easily. Element plans and 3D models for production can be created automatically, and checks for identical precast elements (including fixtures and reinforcement) quickly carried out using the unique identifier. As the precast market grows, so will the tools available to streamline the manufacturing and delivery process.

In terms of construction activities, new tools are emerging that help with the construction planning. For example, using Allplan, the position of tower cranes can be checked virtually for collisions before positioning on site. Capacity checks are also available, which are easy to customize and can be linked to specific manufacturer data, such as tower, foundation, and jib dimensions. There are also tools for placing construction site equipment objects and comparing variants, enabling a well-planned construction site layout in the shortest possible time. As contractors look to find more efficiencies and protect profit margins, automation will offer efficiency gains.

Networked Cloud Platforms and IoT

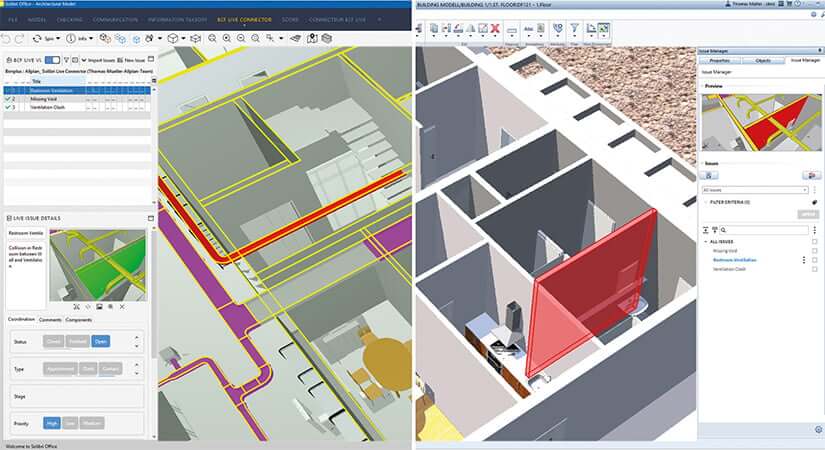

A new term that will grow in popularity in 2023 is Connected BIM. This allows users to connect data throughout the whole life cycle of a building or asset. The digital twin is one way of doing this, enabling outcomes to be optimized based on data insights gained from previous projects. For designers, Connected BIM will enable them to improve both information transfer and integrity, while also allowing different solutions to be connected (such as rule-checking tools like Solibri Inside with model authoring tools like Allplan).

In terms of operations, facilities management is already moving towards digital twins simply by adding sensors that enable Building Lifecycle Management. This introduces live data monitoring into the decision-making process, particularly when considering future operations. This could include areas such as energy consumption, space allocation, asset performance, usage efficiency optimization and structural health monitoring. Connecting this information to other sources through BIM will enable further insights and feedback actual performance data regarding designs to better inform future projects.

Mobile Computing and XR Experiences

Another emerging technology that will gain more attention this year is the Metaverse. Essentially an expansion of extended reality (XR), the Metaverse has the potential to offer project teams a unique environment to collaborate in. While virtual reality lets a digital twin of a building be explored, the intent is for the Metaverse to allow project teams to come together in an immersive experience. Here, the virtual project model could be interacted with by multiple team members and stakeholders using VR equipment. It could also allow a central project setup where all the model data could be hosted. The potential benefits of the Metaverse in terms of collaboration, design prototyping, BIM coordination, and visualization are too great to ignore, so expect to hear more about this latest trend.

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com