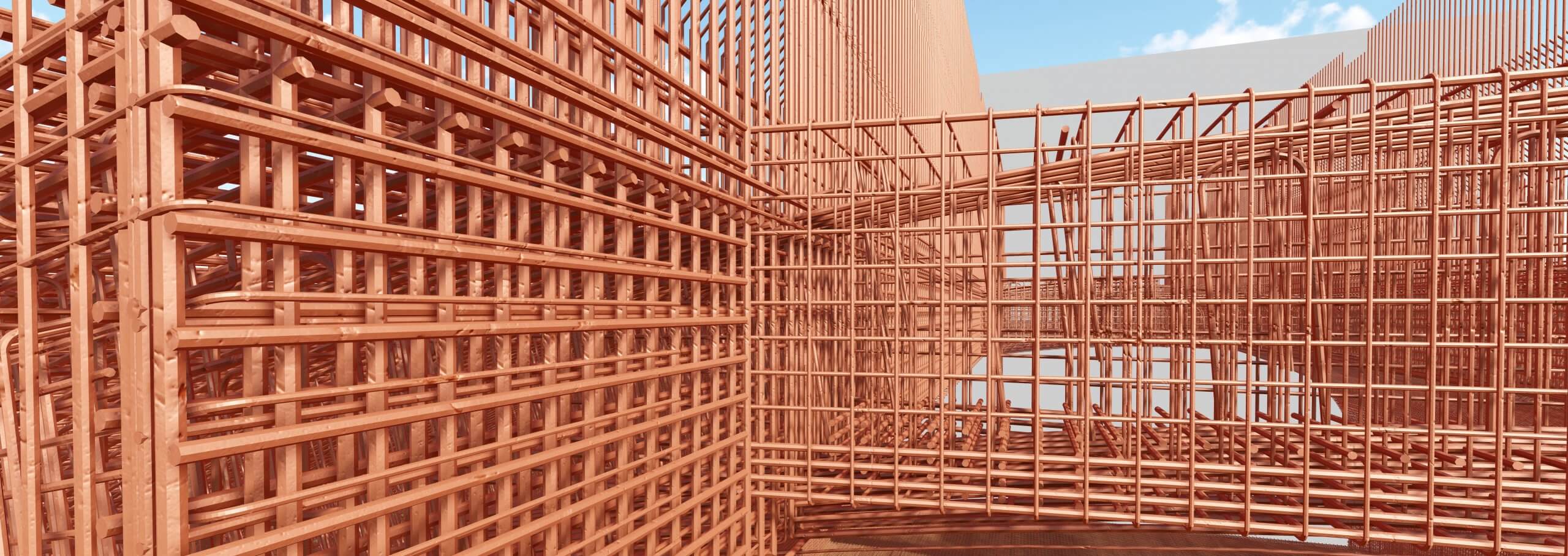

Why should business use 3D rebar detailing software?

Moving from 2D to 3D rebar detailing with Allplan offers many advantages for detailers as the rebars can be fully visualized in 3D while being detailed quickly using familiar 2D workflows. However, detailing rebar is only a part of the job; other tasks such as visualization, document and drawing production, change and project management activities also cost a lot of time. Whether the detailing process is operated completely in-house or by outsourcing a professional drafting company, 3D rebar detailing provides businesses in AEC industry significant benefits. It is not only transform the rebar detailing process, but businesses can also enjoy profits that arise as a result of time savings.

Improve Quality and Win More Work

In comparison to 2D rebar CAD software, the accuracy or in other words – the quality is greatedly increased with 3D rebar detailing software. As the quantity or section and view can be derived automatically from the 3D model, potential mistakes can be prevented. This will resulted in improved accuracy, fewer errors, which in turn leads to less re-work and fewer wasted materials during production. The increased quality also helps businesses to gain a better reputation with contractors and engineers and potentially lead to more work.

Accomodate More Projects with 3D Rebar Detailing Software

3D rebar detailing software help to create a complete set of rebar documentation faster which will enable detailers to take on more projects in the same amount of time. Information can be extracted quickly and automatically from the 3D rebar model for reports including bending schedules and quantities. Besides, cross-sections and views can be generated in seconds while drawing layouts can then be created in a fraction of the time. Accelerated documentation production means more projects can be accommodated, allowing a business to grow without the need to hire and train additional staff.

Protect Profit Margins

The automatic updating of the 3D rebar model and drawing layouts means that changes are less likely to affect profit margins. With Allplan, the 3D model is the source of all the information which is contained in drawings. When the model changes, views and sections are updated automatically without the need to be manually re-drawn. Besides, reports can be re-generated and re-inserted into the layout in seconds. This will help to save a considerable amount of time comparing to 2D methods. Clients are satisfied as their changes are accommodated quickly while companies are happy as their profits are protected.

3D Rebar Detailing Software Helps Businesses Stay Competitive

Engineering firms sometimes outsource a professional drafting company for rebar detailing due to the lack of in-house manpower and/or capabilitites. However, the effort required for coordination and quality assurance could be quite high. The higher productivity that Allplan enables – up to 30% – can offer business another choice to carry out the tasks by themselves instead of outsourcing. At the same time, the time saving and increased quality help companies to stay competitive.

Work Smarter

Thanks to smart and automated tools of 3D rebar detailing software , precision, quality, productivity can be improved and changes are easier to manage. This enables drafters to be more productive. Therefore, engineering and precast companies can save a significant amount of time and take on more work with the same staff as a result, providing an instant boost in profit margins. In addition, rebar detailing companies can increase their competitiveness by providing a high-quality service that other firms cannot. Hence, working smarter with 3D rebar detailing software is essential for business to stay competitive and profitable.

Source: blog.allplan.com

Download Allplan AEC 2022 Now!

Allplan 2022 mang đến phương pháp làm việc tích hợp cho các kiến trúc sư, kỹ sư và nhà thầu trên một nền tảng duy nhất từ thiết kế ban đầu đến khi hoàn thiện thi công trên công trường. Các quy trình làm việc được tích hợp liền mạch giúp rút ngắn quá trình phối hợp, làm tăng hiệu suất và giá trị của dự án – mang đến khả năng xây dựng ở mức tốt nhất.

- Mang đến sự hợp tác nhịp nhàng giữa kiến trúc sư và kỹ sư.

- Tự do chuyển đổi giữa các phương pháp làm việc 2D và 3D

- Xem xét việc triển khai thi công ngay trong giai đoạn thiết kế

- Mang đến hiệu suất tối đa cho các dự án lớn và phức tạp

- Công nghệ đám mây mạnh mẽ hỗ trợ hợp tác liên ngành

- Quy trình làm việc tích hợp giúp tăng hiệu quả và giá trị của dự án

NEWSLETTER

Nhận các thông tin về Allplan qua email

Giải pháp toàn diện cho kỹ sư và kiến trúc sư

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com