Maximizing Efficiency in Precast

Precast concrete has become a popular building material thanks to a range of market conditions which are driving unprecedented growth in the sector. The efficiency, cost-effectiveness, and enhanced eco-friendliness of precast components has attracted increased interest and driven demand. In fact, according to Grand View Research, the global precast concrete market is set to grow by 45% from USD$95.76 billion to USD$139.33 billion between 2021 and 2028.

However, change and growth also bring challenges, not least among them finding ways to cope with the increased workload efficiently. The solution lies in specialist precast concrete software programs that have been developed specifically for precast processes. Whether you want to collaborate more effectively with your project partners, manage your design and production process more efficiently, produce precast components perfectly each time, or attract and retain the best staff so you can take on more projects, the right concrete detailing software solution can help you achieve these goals.

Developing an Effective Workflow

One of the crucial aspects to handling increased demand is an effective precast workflow. Both design offices and precast concrete plants can significantly increase the efficiency of their workflows with software developed specifically for the needs of the precast industry. For example, the powerful tools in Allplan Precast, Tim, and mTim support precast concrete plants and design offices across all project phases: from the impressive 3D tendering model and high-precision 3D precast model to the complete sequence and production planning, as well as clear 3D stacking and seamless billing data. The automated workflows that ALLPLAN’s solutions enable result in enormous efficiency gains, thereby ensuring that projects can be delivered profitably.

Planning for Success

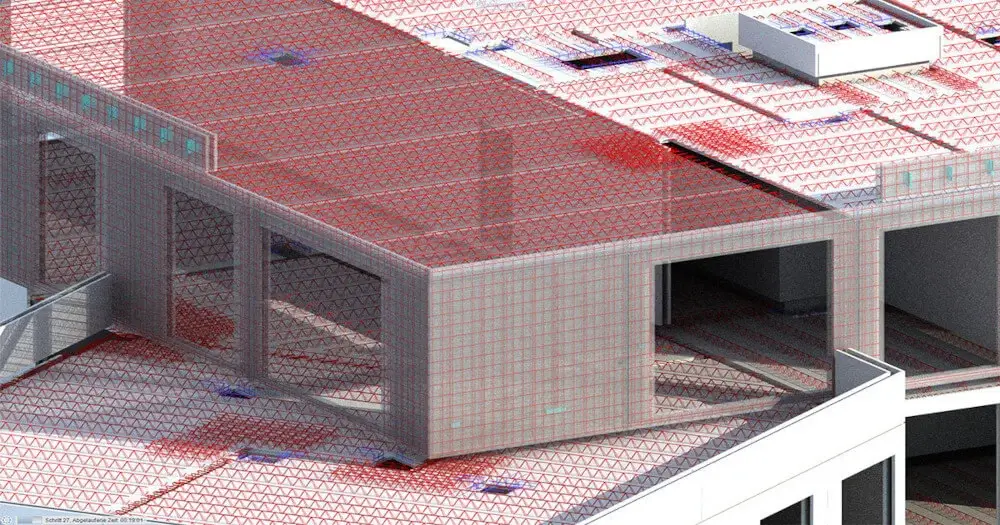

During the planning and design stage, moving to a digital, 3D workflow with software like Allplan helps improve the efficiency of the entire project. It enables accurate cost estimations as volumes and quantities can be calculated automatically from the architectural model. Where design is required, precise 3D models can be created quickly and easily and adapted just as rapidly. Reinforcement is also significantly faster and more accurate, as is creating the required documentation. Even fixtures can be handled more efficiently with a 3D solution like Allplan. And with integrated open BIM support, collaboration with other disciplines is straightforward.

Preparing for Perfect Performance

Allplan Precast provides a complete process chain right through to work preparation, production, and on-site installation. This is supported by our Tim solution, as well as the mobile application, mTim. The production stage can benefit from 3D models and digital workflows just as much as the planning stage. For example, accurate production information can be sent directly to the manufacturing machines for high-quality production. In fact, a 3D solution is ideal for optimizing production planning, enabling informed decisions to be made. Construction scheduling and sequencing can be simulated and coordinated so issues can be addressed before any works take place. Similarly, delivery planning and visualization can be carried out in Tim to catch problems early. Essentially, an efficient, digital workflow provides better process management and control over the entire production phase.

Choosing the Best Precast Software Solution

The right precast concrete software helps overcome the challenges that precast designers and manufacturers face, while also enhancing productivity – both now and in the future. For an in-depth look at how to address the unique challenges of the precast boom, download our whitepaper, Maximizing Efficiency in Precast: Optimizing Workflows to Benefit from the Prefabrication Trend.

To experience Allplan’s innovative features, download the 14-day free trial now and bring your projects to higher quality.

Source: Maximizing Efficiency in Precast

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com