How precast is the leading solution in construction

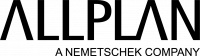

Experts in the construction sector forecast a bright future for precast elements: between 2021 and 2028, the worldwide precast concrete industry is expected to increase at a rate of 5.3 percent on average annually. The precast concrete market was worth roughly USD 92.14 billion in 2020, and it is expected to reach USD 139.33 billion in 2028[1]. According to the Global Construction Report, the average annual growth rate of the construction industry as a whole is predicted to be barely 3.2 percent. The multiple advantages of this technology can explain why industrialized construction is developing faster than the rest of the construction sector.

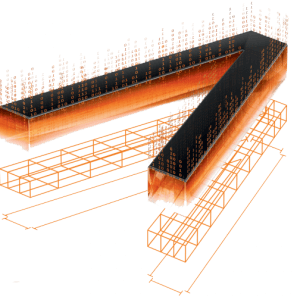

Photo source: Allplan Software Engineering GmbH

Fixed rates, on-time delivery, and precision are advantages of prefabrication.

Building components are prefabricated to the millimeter at factories and then brought to the construction site just in time when prefabricated elements are utilized. A crane then takes over the assembly and relocates the prefabricated parts to their proper locations.

What are some of the real-world benefits of industrialized construction? Off-site manufacturing brings the advantages of industrialization to the construction sector, resulting in increased productivity, shorter lead times, and greater precision. Another significant benefit is the extreme precision with which cost and time estimates are made – especially given that, according to McKinsey, traditional construction projects typically take 20% longer than expected and cost up to 80% more. Contractors, on the other hand, profit from fixed rates and predictable delivery dates with precast projects. Exact production planning and accurate control of the production planning in the precast factory are the reasons for the high reliability.

The conditions of production also play a significant effect. For precast concrete pieces, for example, manufacturing parts in factories – which are totally weatherproof – ensures a consistent high quality level. When compared to in-situ concrete, the correct software guarantees that the raw materials used are optimally measured and that reinforcing amounts can be greatly reduced.

Thanks to precast parts, construction is more resource-efficient.

Precast concrete elements are also environmentally friendly: concrete is made entirely of natural resources that are mined and produced in close proximity. Furthermore, this construction material can be virtually entirely recycled and reused, for example, in road construction. Furthermore, research is always creating new techniques to lessen the environmental imprint of concrete, particularly cement. Local neighbors benefit from less noise and dust pollution as a result of the shorter building duration. Precast concrete is also extremely long-lasting and fire-resistant.

ALLPLAN offers specialized precast design software.

The construction sector can profit from the efficiency benefits that the automotive industry has enjoyed for years thanks to industrial prefabrication of pieces. It’s no surprise that industry leaders like Tesla have long used precast materials to construct their new manufacturing plants. As a result, the precast industry can serve as a model for the entire construction industry’s digitalization.

New approaches of designing, on the other hand, necessitate a reassessment of appropriate tools. When it comes to such a transformation, having a dependable software partner who specializes in the design and details of precast elements is critical. The professionals at the Competence Center Allplan Precast are well familiar with the unique needs of the precast industry, which is why their software products Planbar and Tim were created exclusively for precast projects. For the ease and efficiency that Allplan Precast provides, huge precast projects like the Gigafactory Berlin relied exclusively on Planbar for their staircases and stair landings due to this in-depth knowledge.

Contact us to know more about our precast solutions!

Source: blog.allplan.com

NEWSLETTER

Receive information about Allplan via email

All-in-one solution for engineers and architects

Download Allplan 2022 Now!

ALLPLAN 2022 – THE MOST POWERFUL BIM SOLUTION FOR YOUR SUCCESS

> Maximum performance for large and complex projects

> Powerful cloud technology for interdisciplinary collaboration

> Intergrated openBIM workflos for structural engineers

Test the full version of Allplan 2022 for 30 days free of charge and with no obligation. Simply download the software and experience all the advantages for yourself.

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com