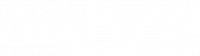

© Anchor Plaza Downtown, Z Group-Birou de Structuri SRL, Bucharest, Romania

Overcoming 5 Common Challenges of Reinforcement Detailing

Reinforcement detailing drawings are always a challenge – producing them to the required quality standards and in the given timeframe whilst ensuring a reasonable profit margin is a difficult task. In fact, ensuring quality, productivity, and profitability for every reinforcement project irrespective of the location or complexity is a constant juggling act for engineering and reinforcement detailing companies. ALLPLAN understands this, which is why Allplan Engineering has been specifically developed to overcome these five common rebar detailing issues.

1. Ensuring Profitability

Staying profitable means streamlining processes and finding ways to work more efficiently. With Allplan, the learning curve for reinforced concrete detailing is much reduced – creating bar shapes or placements using a familiar point-by-point workflow is possible. However, it is also easy to switch to the next level and model 3D reinforcement by simply expanding the bar shapes and placements to adapt to the edges of a 3D object. Allplan is therefore like using an intelligent drawing board: by working in sections, the 3D reinforcement model is created automatically in the background.

For standard objects like beams, columns, or walls, the workflow can be even more efficient by using automated reinforcement, where the reinforcement and sections are created automatically. This simplified process helps protect profit margins by removing unnecessary steps and accelerating the schedule.

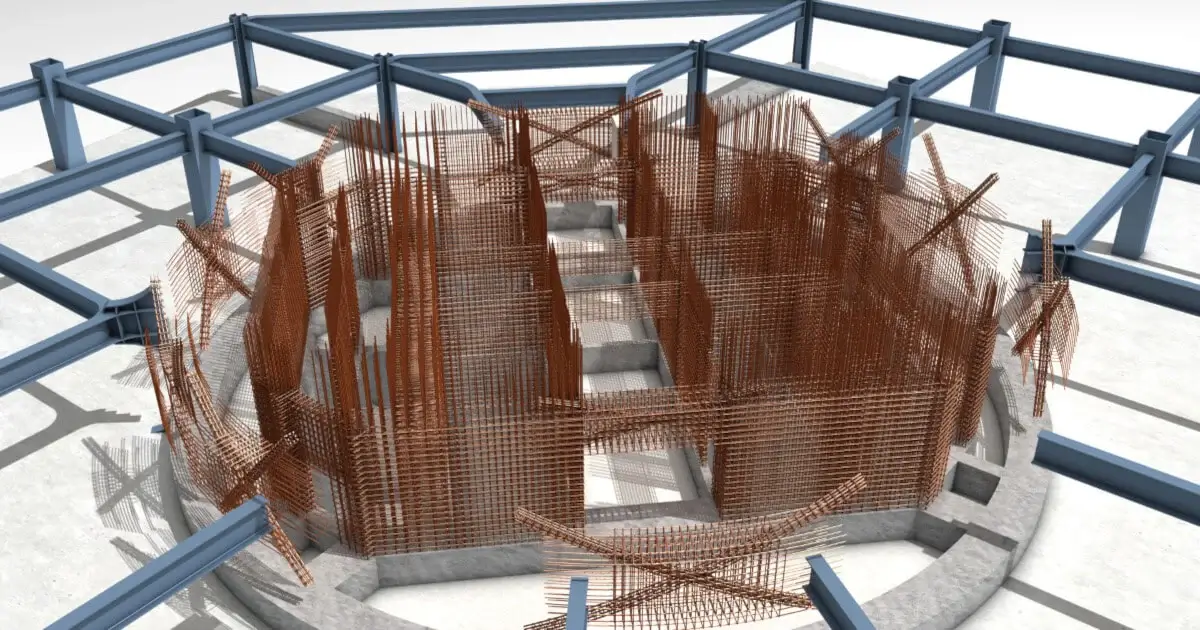

© Reconstruction and Extension of Ferihegy Airport, KÉSZ Building and Construction Company, Budapest, Hungary

2. Achieving Quality

The more complex the structures become, the more important it is to have good quality reinforcement detailing drawings in order to avoid unnecessary queries from the construction site. The consistent information offered by Allplan can help achieve this quality. For example, in Allplan, it doesn’t matter where a modification is made – in the global view, in views or sections, or in the 3D model – the data will always remain consistent with each other.

The content of the views, sections, legends, and reports is based on the 3D model. The advantage of Allplan is that modifications can be made to a view or section, and the 3D model will be updated as will all other views, sections, and legends, too. The layout in the views and sections is kept, saving the time required to update everything as well as maintaining consistent quality by removing the potential for errors to creep in.

3. Maintaining Productivity

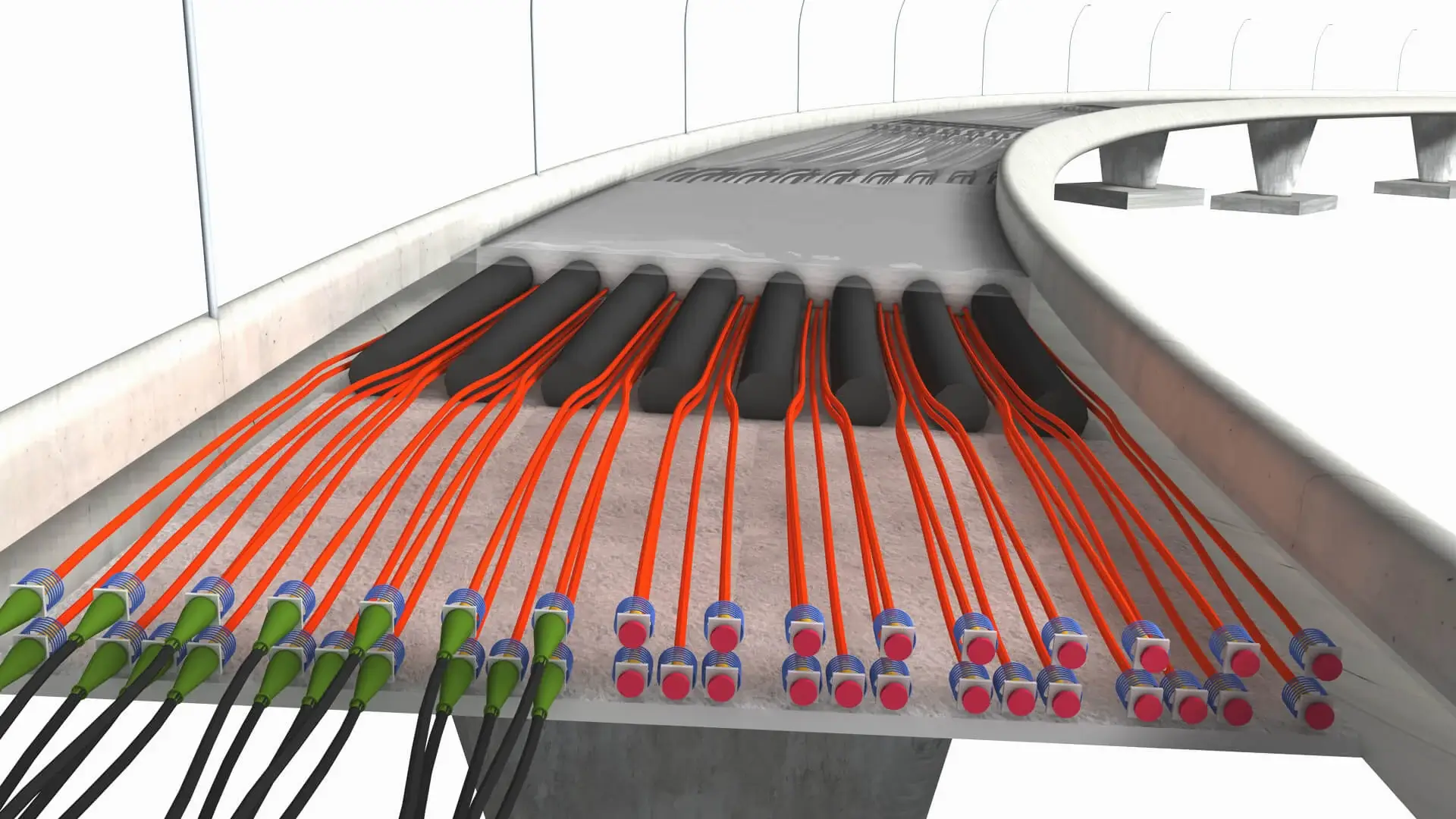

© Fly-Over-Krensheide, Movares, Utrecht, The Netherlands

Even in more complex structures, there are always reinforcement details or reinforcement zones that repeat. Creating the reinforcement detailing drawings for these zones again and again is a lot of work, which takes up valuable time. By reusing layouts or reinforcement zones for repeating components, productivity can be maintained.

The improved algorithms in the typical Edit tools – including Copy, Move, Rotate, Copy and Paste, Rotate, Mirror without Copy, and Copy and Mirror – make it easy to reuse an already finished reinforcement detailing drawing. The model as well as all selected views and sections retain their position in relation to one another. In the end, the new reinforcement detailing drawing can be created rapidly with only a few adjustments. Another benefit is that the position of the reinforcement in the model is always correct when exporting the drawing using IFC. With this efficient workflow, what would have taken two days can now be ready in two hours.

4. Working Efficiently

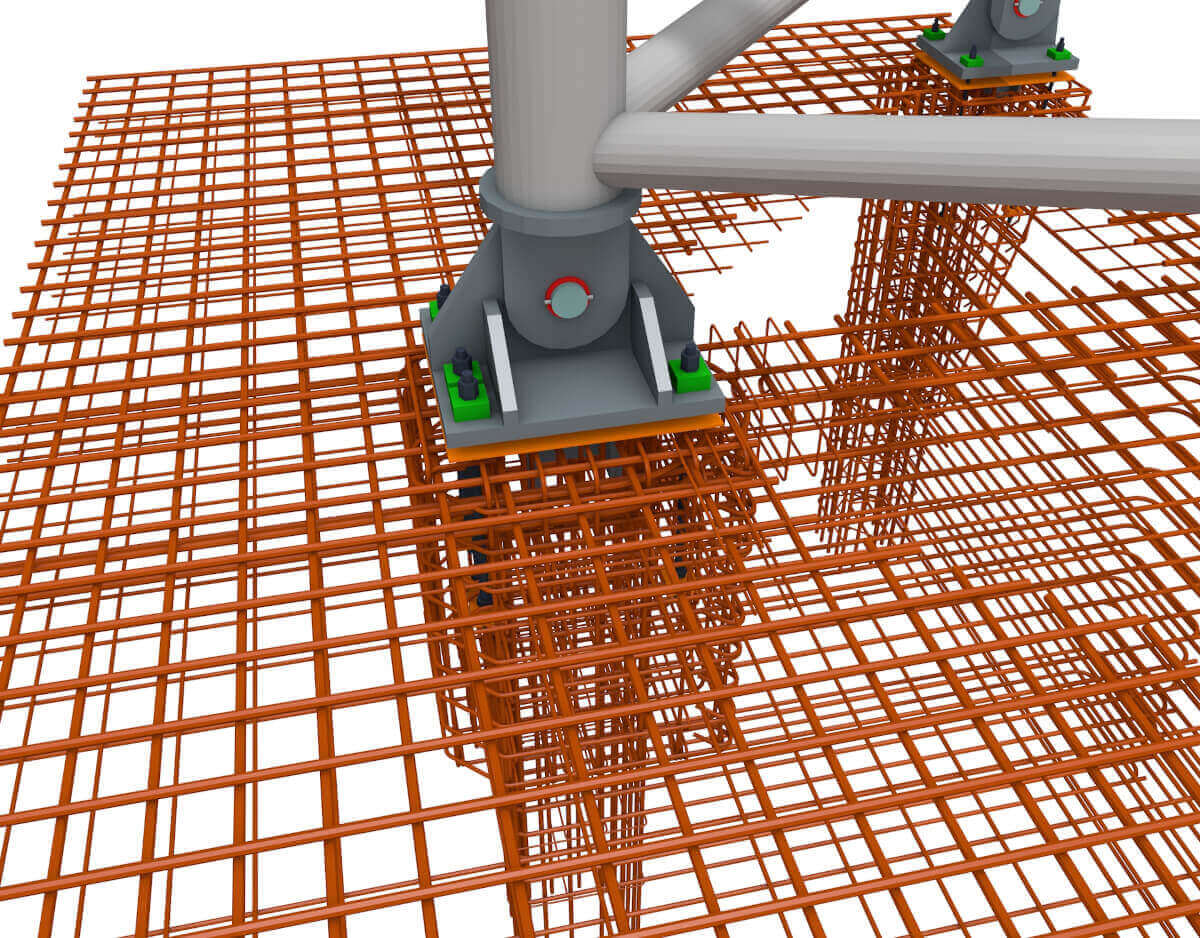

Free-form structures can be difficult to reinforce efficiently. The wide range of reinforcement detailing tools in Allplan have been developed specifically to overcome this issue. One of the most used tools is Sweep Bars Along Path, which enables easy reinforcement of components that appear complex at first glance.

Sweep Bars Along Path is a really magical tool; simply define the bar shapes and the location of the longitudinal bars in as many sections as you like and select the paths for the sweep algorithm. With this tool, even free-form reinforcement can be created quickly and easily in Allplan.

5. Incorporating Local Standards

Ensuring compliance with country- or region-specific standards is another aspect that can affect productivity, quality, and profitability. To address this, Allplan offers a wide range of options for adapting reinforcement detailing to country-specific requirements. In addition to the choice of country and language, around thirty different rebar standards can be selected. If this is still not enough, customized reinforcement detailing standards can be defined in Allplan.

In many countries, predefined shape codes are expected when reporting the quantities of the created reinforcement. The existing shape codes are evaluated by the new Shape Code Manager, which can even be adapted to individual office or project standards, too. Custom shape codes can be defined, or existing ones adapted as required and then presented in legends. Another benefit of the Shape Code manager is it will automatically update the units to the required standard, as well. With this tool, international projects or projects with demanding requirements for the bending shapes can be optimally implemented.

© Fly-Over-Haarlem, Iv-Infra b.v., Nieuwegein, The Netherlands

Conclusion

When it comes to concrete detailing software, Allplan Engineering has been designed to make the entire process more efficient by providing tools to overcome the common challenges in the rebar detailing workflow. This way, quality and productivity – and therefore profitability – are maintained for engineering and reinforcement detailing companies. If you are looking for rebar detailing software, why not try a free, 30-day trial of the latest version of Allplan Engineering to see how these workflows can accelerate your rebar detailing processes.

ALLPLAN is part of the Nemetschek Group.

-

Singapore: ALLPLAN Software Singapore PTE. LTD. |

4 Battery Road #25-01, Bank of China Building

49908 Singapore - customercare.singapore@allplan.com